Zf Transmission, 4wg200 Transmission, 6wg200 Transmission manufacturer / supplier in China, offering Original Zf Transmission 4wg200 6wg200 Ap400 Series Gearbox Assembly, PC360 Excavator Track Chain Link Guard for Undercarriage Parts 21, Komatsu Excavator Skeleton Bucket and so on. ZF - POWERSHIFT TRANSMISSION 4 WG-92/98 TSC zf 4wg200 service manual. Zf 6wg200 transmission repair manual. Zf transmission repair manual free download. All details in these Operating Instructions refer to the basic version of the ZF-Ecomat transmission. Due to the large number of installation options, no precise informati- on can be. M, ZF 5 M, ZF 10 M, ZF 12 M, ZF 15 M, ZF 15 MA, ZF 25 M, ZF 25 MA, ZF 30 M, ZF 15 MIV, in particular for - power plant suppliers - shipyards - craft owners The ZF M manual is intended as an aid for handling ZF M transmissions and will answer all questions that may arise in daily operation and in connection with the installation and repair of ZF.

Product Description

Zf 6wg200 Transmission Repair Manual

Atv Repair Manual

Electronic workshop manual contains repair and service informartion, maintenance instructions, a complete description of troubleshoot procedures for power transmission ZF WG180 and WG200.

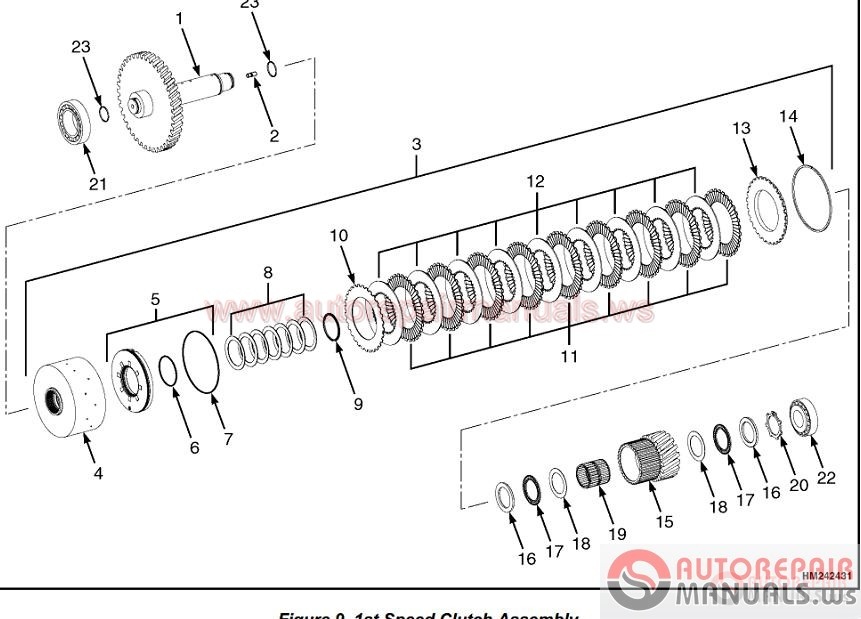

Electronic manual includes illustrations, which help to get a detailed description of all the systems of transmission ZF.

Workshop manual helps to quickly and easily calibrate transmission ZF, fix problems, to solve any problems, find information about the equipment.

In this Workshop Manual, the Disassembly and Reassembly of several Transmision Versions as well as Assemblies are treated.

This manual comes in PDF. For work with manual you need to install the application Adobe PDF Reader.

CONTENTS:

Preface

General Woking Instructions

Important Labour Safety Instructions

Denomination of Legal Standards

Convesion Table for Dimensional Units

Torque limits for screws

Inscriptions on the Model Identification Plate and Instructions

Possible versions Additional equipment

List of lubricants TE-ML 03

1. Electro-hydraulic gearbox control:

1.1. Cast-iron gearbox control;

1.2. Aluminium sand-casting gearbox control;

1.3. Aluminium die-cast gearbox control

2. Torque converter:

2.1. Disassembly;

2.2. Reassembly

3. Gearbox:

3.1. Disassembly;

3.2. Reassembly

4. Retarder:

4.1. Disassembly;

4.2. Reassembly

5. Axle delclutch:

5.1. Disassembly;

5.2. Reassembly

6. Axle differental:

6.1. Shift-control housing;

6.2. Differential

7. Power take-off controllable under loas:

7.1. Disassembly;

7.2. Reassembly