- Process Simulation Software, Simcad process simulator for process simulation, modeling, optimization, and Predictive Analytics with Lean and six sigma metrics, Applications in Manufacturing, Warehouse, Supply Chain, Logistics, Automation, Healthcare, etc. Process simulation software, free download, Free Trial & Free Demo.

- Nov 09, 2020 The software is a free download and is available from automation direct. This software will now allow you to test or troubleshoot your program without the physical hardware present. The entire family of controllers can use the simulator. P1000, P2000, and P3000 emulation can happen on the following parts of the productivity series hardware.

LTE MAC Lab offers a free version. LTE MAC Lab is simulation software, and includes features such as 3d modeling, turbulence modeling, presentation tools, Agent-Based modeling, and industry specific database. With regards to system requirements, LTE MAC Lab is available as SaaS software. Costs start at $4000.00. LogixSim is a suite of software products that provides “real world” laboratory simulation of electricity, electronics, robotics, and programmable logic controllers. It combines four simulators and offers unlimited possibilities for the design, testing, and debugging of control devices and automated equipment as well as circuit schematics and systems.

In my quest to produce online training classes I have been investigating some of the different types of industrial automation and PLC simulators available.

My intent here is to find two different things: 1. A PLC programming simulator that is free or very low cost that can be used by students on their own computer to simulate and do exercises, and 2. A Process or Machine simulator that includes PLC and HMI programming tools and visualization of components.

One of my requirements is that the software be either non-brand-specific, or multi-platform. In my PLC training manual (recently published by the way), I use a generic addressing method as shown in this image. The intent is to be able to substitute any platform’s address where the red caption is, or make it invisible if using tags. The blue text could then be used either as a symbol (for non-tag-based platforms) or as a tag. All of this would need to be accessible in a list such as a symbol or tag database. This pretty much eliminates any of the major brand’s emulators, though I have been using Allen-Bradley’s RSLogix 5000 software with aliases to generic tag structures with some success. The problem with that is that it is far too expensive for students.

The center image above shows a screenshot of “LogixPro”, available from The Learning Pit. I haven’t checked this out, but at only $35 it looks like a good option for those wanting to play around with Allen-Bradley’s SLC and Micrologix platform. Again, for me this is too brand-specific. It also looks like The Learning Pit kind of does what I am planning to do, online PLC training.

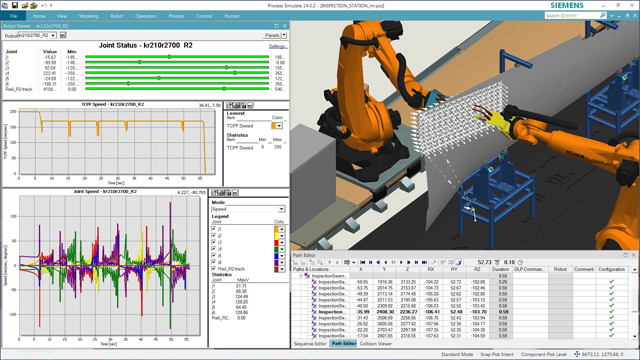

I also would like to link the simulation program to some graphics so that students can visualize their programming results. There are a lot of packages that simulate factory floor equipment. In the picture at the top of this post is Siemen’s PLM (Product Lifecycle Management) software. This can be used to create a virtual factory floor. It doesn’t interface with the Siemens Step7 software though, and even if it did it would hardly be generic…

I found a lot of other plant floor simulators when checking online. This list of simulation and modeling software on Automation World’s site had a lot of good products from Cybosoft, Mynah, Cenit and others, but they are not compatible with PLC or automation software.

Last week I also participated in a demo of Famic’s Automation Studio. There are two versions of this software, the Professional Edition, and the Educational Edition. Unfortunately I don’t qualify for the Educational Edition, which would probably be less expensive than the $6000 price tag of the Professional.

The demo was pretty cool. A PLC program can be written that will drive pneumatic and hydraulic circuits, which in turn can be embedded in a graphical simulation of a machine or process. The software seemed heavily oriented toward the pneumatic and hydraulic simulations, libraries of components could be imported from several manufacturers and placed into the simulation. There are drawing tools that can be used to animate the visualization, but the programmer would have to be pretty adept at creating graphics; it is not 3D. The PLC software itself is pretty basic, but it does appear to contain most of the instructions needed for training. There is also electrical circuit simulation capability.

Unfortunately for me, the price is still too high to use on a per-student basis. I could buy an actual PLC, HMI and software for each student station at that price, though the pneumatics and hydraulic training capability would be nice. From what I understand, the full-blown design package is more like $20,000.

I also just downloaded Factory I/O’s free trial of PLC simulation software. It is certainly more within the price range I am looking for at 695 Euro’s/seat, and it says it works with Allen-Bradley, Siemens, Modicon and CodeSys. I have 30 days to try it out and will write a bit more after I see what it can do.

Automation Simulation Software Free

Overall there seems to be a lot of stuff out there, but nothing that does exactly what I want it to. I like Automation Studio’s pneumatics, hydraulics and electrical training environment, I could use something like WonderWare, Ignition or A-B’s FactoryTalk View for the visualization part, and maybe something from CodeSys or PLCOpen as a PLC platform, but there doesn’t seem to be much that combines it all together. I am also going to evaluate using a SoftPLC, but I am afraid the cost is going to be exorbitant.

If anyone has any suggestions or comments let me know!

An effective 3D simulation of an automated process does more than clearly illustrate a series of complex equipment moves.

Software For Simulation

Sage Automation can provide our customers with simulations using actual time parameters to prove out a systems throughput capacity. We also have the ability to drive the simulated equipment with the actual PLC code that would run the physical equipment. This ability can shorten the startup and commissioning process, as well as allow Sage to test program changes on a simulation without impacting production on the physical equipment.

Below is a simulation of a Gantry Robot that is used as an Automated Storage and Retrieval System (ASRS) for a drum and bulk tote filling operation.

Drums and totes enter the system, typically in slugs of similar products, and are discharged to the filling operation randomly based on orders.

The 3D simulation allowed Sage to fully test our storage algorithm and optimize our motion paths for the most efficient operation.

Once the physical equipment was manufactured, the same software was used to drive it, with only minor changes.

The next 3D simulation shows a multi-pick and sortation gantry system. This simulation fills the envelope with the daily production of goods and exports the day’s delivery orders in reverse sequence for ease of loading the trucks for their routes.

Automation Simulation software, free downloads

Sage Automation would be happy to simulate a solution for your project.